Carli Suspension

2003-2009 RAM 2500/3500 Carli Coil Bucket Gussets

2003-2009 RAM 2500/3500 Carli Coil Bucket Gussets

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

KEY FEATURES:

- 1/4″ Cold-Rolled USA Steel Braces Factory Frame Motor Mounts

- Converts Mounting Channel to Eyelet for Maximum Strength

- Includes Extended Hardware

- Coil Bucket Gussets Brace the Factory Brackets to the Frame

- Fitment: 2003-09 Ram 2500/3500 4×4

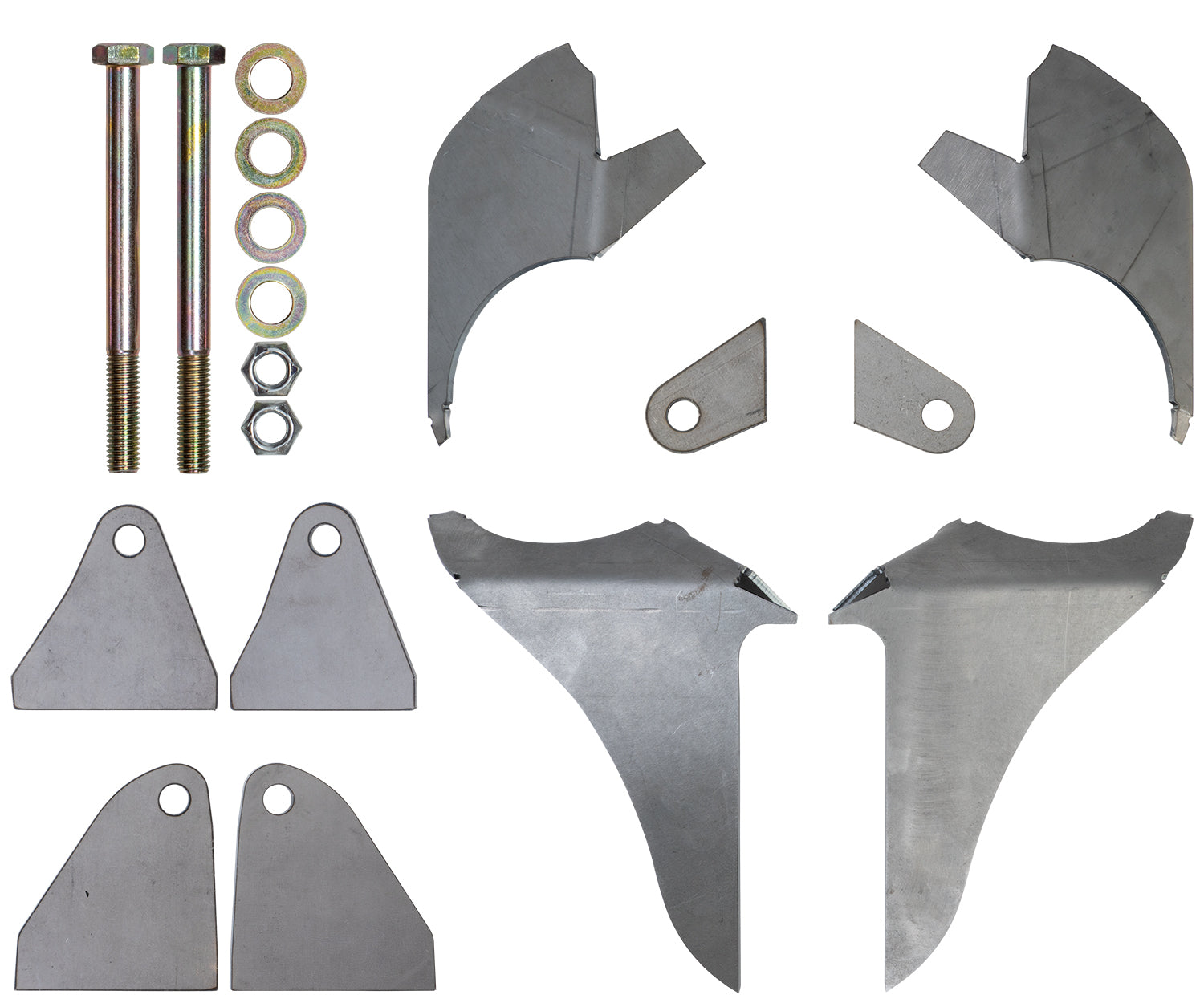

Coil Bucket Gussets

Next up, the factory coil buckets. These have been a known weak point since we installed our first set of 3.0″ Kings on a 3rd gen in the mid 2000’s. The flex of the coil bucket/frame junction is responsible for the shock-tower brace we provided with our original billet shock towers. This brace tied the coil buckets together over the top of the motor to prevent this movement.

This was a losing battle. People who modify to the level that requires this bracing often have aftermarket turbos, bypass oil filters, etc. mounted in the path of the brace. Additionally, the 6.7L was released in 2007.5; the emissions equipment also impeded the installation. What’s the next best thing? Fill in the gaps. These laser cut and CNC bent plates bridge the gap between the coil bucket and frame rail, both in front and back of the bucket. Additionally, we provide tabs to mount your limit straps to the front portion of the brace.

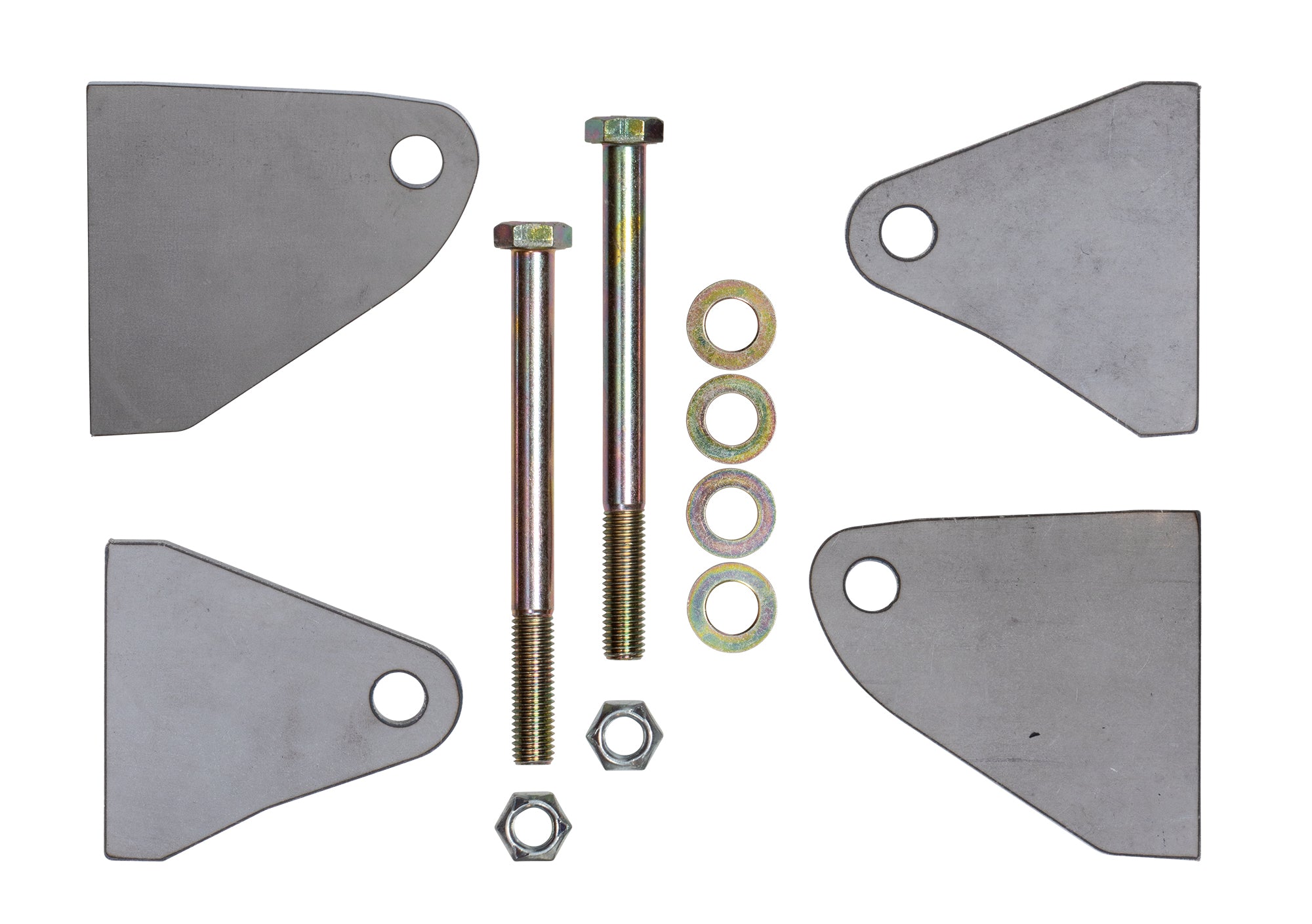

Motor Mount Doubler

The problem here is two-fold. The factory motor-mount is designed as a channel for easy installation. The bolt is installed into the block mount and motor is lowered into the cradle, then tightened. Once seated in the cradle, the only mechanism holding the motor in place (vertically) is the torque of the bolt. In stock power and suspension applications, this is a non-issue. In high horsepower, whoop-pounding situations, this is the Achilles heel of your desert fun.

If you care to know the end of the story, the truck ran and drove; albeit with 3° of camber on each side of the axle (the bend was in the un-braced part of the axle outer C, not the truss itself), and the oil pan was sitting on the crossmember. BUT, it made it home.

To solve this issue, we’ve designed doubler-plates. These inset into the factory motor mounts serving two purposes:

- the 1/4″ steel adds substantial strength to the factory sheet metal when welded in

- Converts to a mounting hole, eliminating the factory channel. This provides a mechanical lock eliminating vertical slippage of the motor in extreme-load situations AND increased the amount of material supporting the mount. It physically cannot peel downward as mine did.

As this adds to the mounting width, new Grade-8 bolts, Washers and crimp-lock nuts are provided to secure the assembly.

Do I Need These?

As with any new product, the question comes up – As a customer, when do I need these? If you’re going to break out the welder for an axle truss and rear shock mounts, order these. There’s zero downside (especially for the price). The motor mount doublers suck to install – I’m not going to sugar-coat it. Getting a torch in there is not easy. In the above picture, I displayed the cleanest weld of the bunch. Even our master MIG welders couldn’t make these pretty, but they’re stuck and serving their intended purpose and that’s all that matters.

If you’re rocking a Pintop, don’t sweat it – these are wasted energy to install. If you’re on a short-arm Dominator… I’d have these on the “maybe” list – be honest with yourself about how you plan to use the truck. If you’re in one of our long-arm kits, just do it and thank us later.

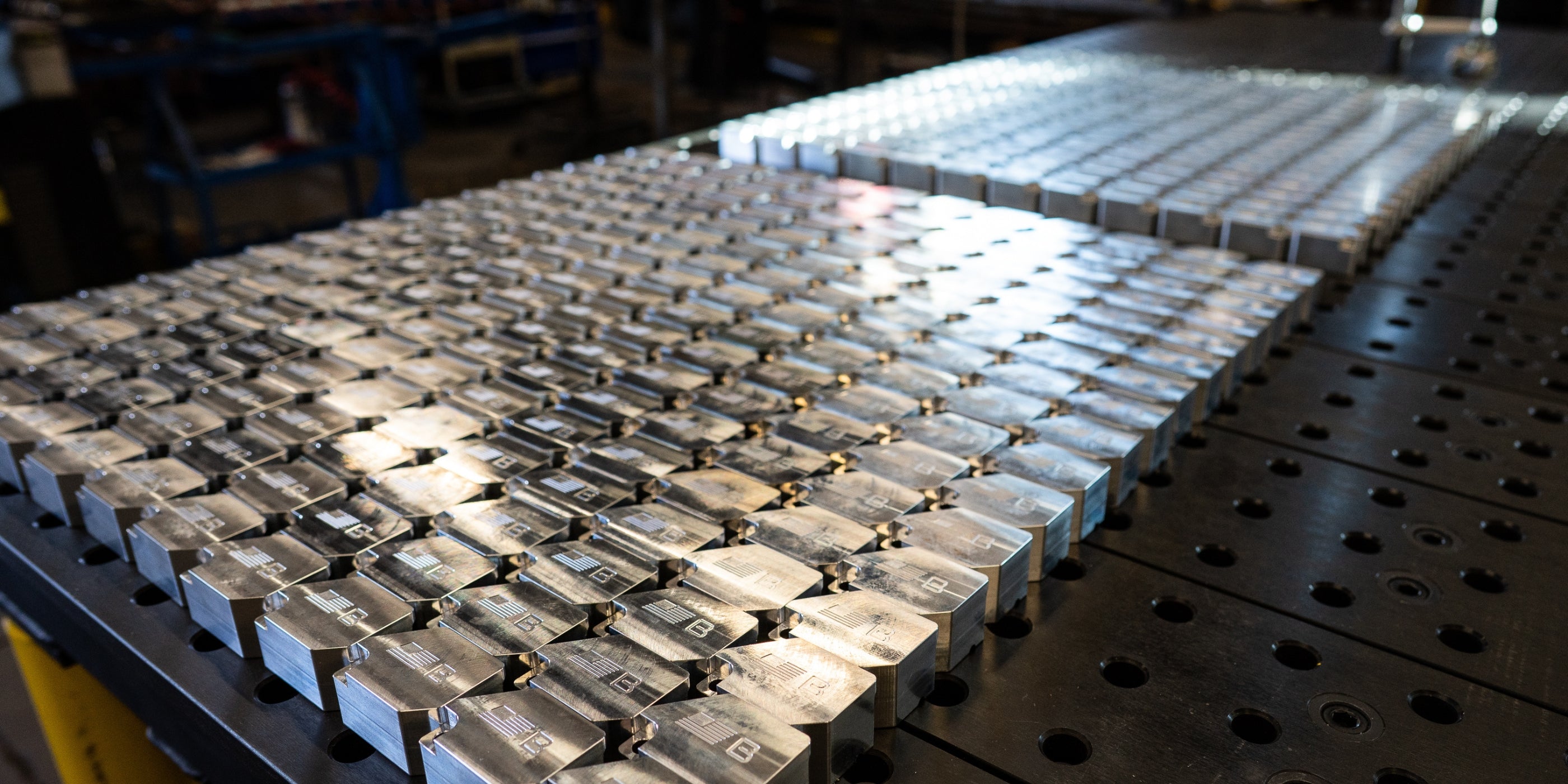

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: