Camburg Engineering

'08-21 200 Series Toyota Land Cruiser Camburg Performance Lower Arms

'08-21 200 Series Toyota Land Cruiser Camburg Performance Lower Arms

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

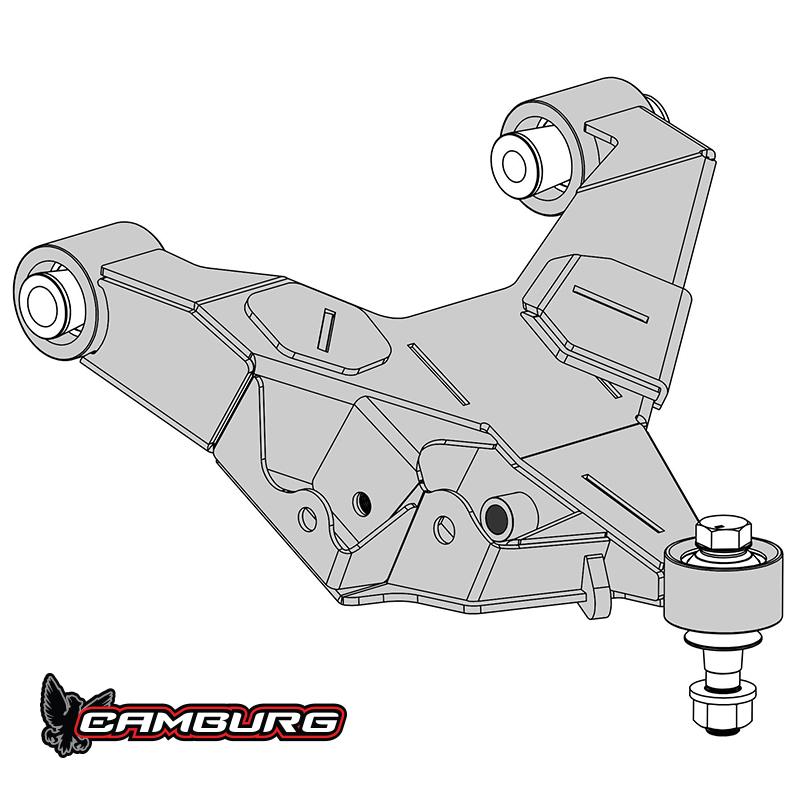

Camburg's performance lower arm kit for the 2008-2021 200 Series Toyota Land Cruiser replaces the stock length lower arm. These lower control arms give you the ability to keep the stock rubber bump stop or upgrade to a FOX or King bump stop for increased bottoming resistance.

When designing these arms, Camburg set them up for maximum useable wheel travel along with the correct shock motion ratio geometry. These arms are also designed to work with the OEM front sway-bar.

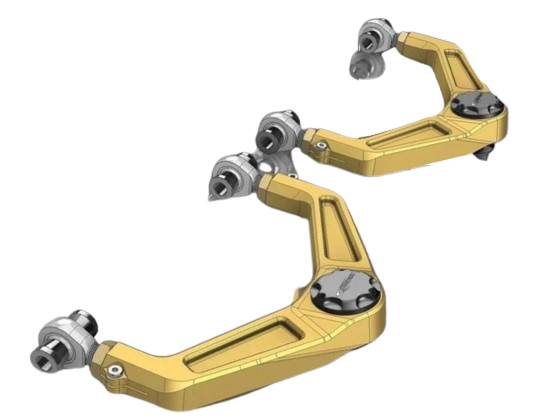

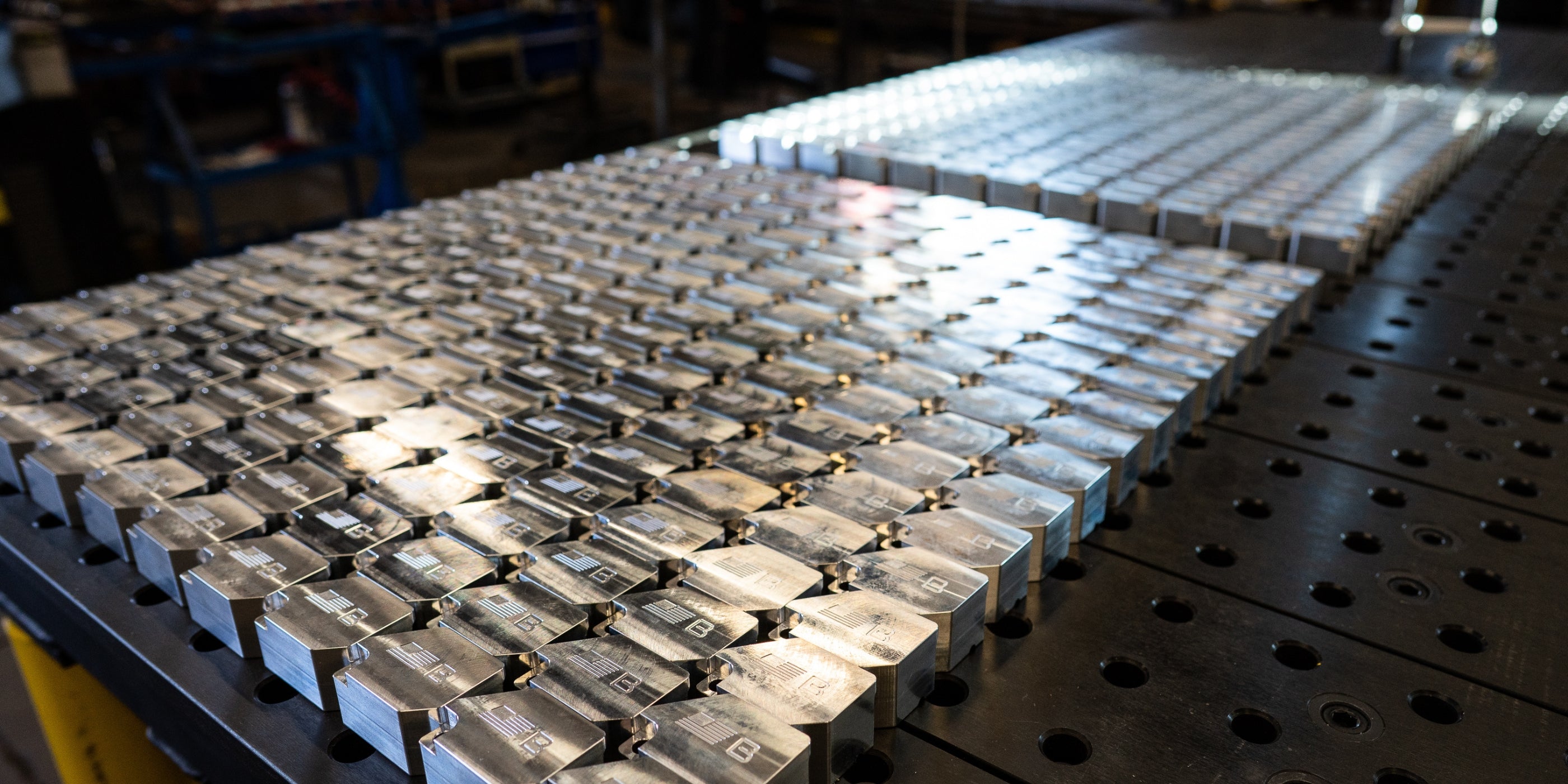

The arms are CAD designed, laser cut, CNC formed, MIG welded, powder coated Camburg gray and are ready to install with all the necessary hardware included. These are by far the strongest stock length aftermarket arms out on the market. Combine these with Camburg's KINETIK billet upper control arms for the ultimate setup.

KEY FEATURES:

- Stock length replacement

- Strongest lower arms on the market

- Uniball frame & spindle pivots

- Made in the USA

SPECS:

- TRACK WIDTH: Stock

- WHEEL SIZE: 17-20 in

- MAX BACKSPACING: 6.00 in

WHAT'S INCLUDED:

- Lower control arms (stock width)

- Stainless uniball spacers

- AN aircraft bolts and hardware

KIT DETAILS:

CAD/CAM engineered, the arm is considerably stronger than the sheet metal stock arm and was designed to maximize ground clearance and off-road performance. It has internal gusseting and pivots on FK 1″ uniballs at the frame rather than cheap rubber or polyurethane bushings that constantly bind and flex under braking. Uniballs allow for zero binding when the suspension cycles up and down and has zero flex under braking so your geometry and alignment is always consistent. With Toyota trucks being aligned by the lower arm, a uniball setup also allows for a bind free adjustment and you’re able to torque all the bolts without putting it into a bind. Since the uniball spacers are 1.50” in diameter, you have better clamping force in the frame mounts due to the increased surface area which keeps the holes from ovaling out over time unlike a small diameter sleeve used in a bushing. This also keeps the alignment cams from loosening up from off-road use.

Camburg eliminated the weaker lower ball-joint with an FK 1.00″ uniball at the spindle for maximum strength and articulation. No modification to the spindle taper is necessary as Camburg uses machined heat-treated stainless-steel mis-alignment spacers that adapt the uniball to the tapered ball-joint spindle bore.

To attach the spindle to the uniball we use a AN 3/4″ hex aircraft bolt. They have a specific shoulder/grip length and the head design yields higher tensile and shear strengths compared to any Grade 8, 9 or 12.9 bolt. They are made to the highest quality control standards out there.

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: