Neo-Synthetics

Waterproof Bushing Grease Tube Neo Oil

Waterproof Bushing Grease Tube Neo Oil

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

NEO Waterproof Bushing Grease is a versatile, pure synthetic, completely waterproof grease containing PTFE. It is formulated to seal out water and lubricate under the most adverse conditions.

NEO Waterproof Bushing Grease with its highly adhesive qualities and high load-carrying characteristics forms a tough durable film of lubrication that prevents metal-to-metal contact even under severe shock loads.

Our Bushing Grease is also U.S.D.A. H-1, which gives it full acceptability for use in ALL areas where incidental food or potable water contact may occur.

Usage – NEO Waterproof Grease with its waterproof and chemical resistant capabilities is an excellent lubricant on all sliding surfaces, gears and slow to moderate speed bearings (about 1000 RPM maximum) operating in Wet or Dry conditions from -22 degree F to 350 degree F.

Due to its pure synthetic base, coupled with the addition of sub-micron size PTFE, NEO Waterproof Grease is an excellent choice for applications in many industries, which requires a clean, tenacious, anti-wear grease.

Because of its U.S.D.A. H-1 NEO Bushing Grease is outstanding for use in food processing plants, where equipment wash down is an everyday requirement and water industries, where contamination with conventional petroleum lubricants is a primary environmental concern.

NEO Waterproof Grease is compatible with most rubbers and plastics and is a superior lubricant for O rings.

uses include:

- Open Gears

- Food Equipment

- Slides and Ways

- Sterilizer Chains

- Gasket and O Rings

- Conveyors

- Valves

- Bushings

- Trunnions

- Pool Equipment

Advantages:

- U.S.D.A. H-1

- Waterproof

- Non Melting

- Contains PTFE

- Kosher Approved

- High Metal Affinity

- Chemically Resistant

- Non Staining

- Wide Temperature Range

- Reduces Wear

- Prevents Rust and corrsion

- High Dielectric Strength

- N.L.G.I. Grade 2

- Worked Penetration D-217

- 60 Strokes 280

- 10,000 Strokes 290

- Base Oil Viscosity D-445

- cSt at 100 degreeC 200

- cSt at 40 degreeC 7800

- Pour Point, degreeF D-97 20

- Flash Point, degreeF D-92 350

- Dropping Point, degreeF D-566 NONE

- Evaporation Loss, percent (10hours at210 degree F) D-972 1.0

- Corrosion Preventative Test D-1743 PASS

- Water Washout, percent Loss D-1264 0.01

- Timken OK Load, lbs. D-2509 40

- 4-Ball Wear Scar, mm (40Kg, 75 degreeC, 1hr.at 1200rpm) D2266 0.57

- Dielectric Strength, KV D-877 30

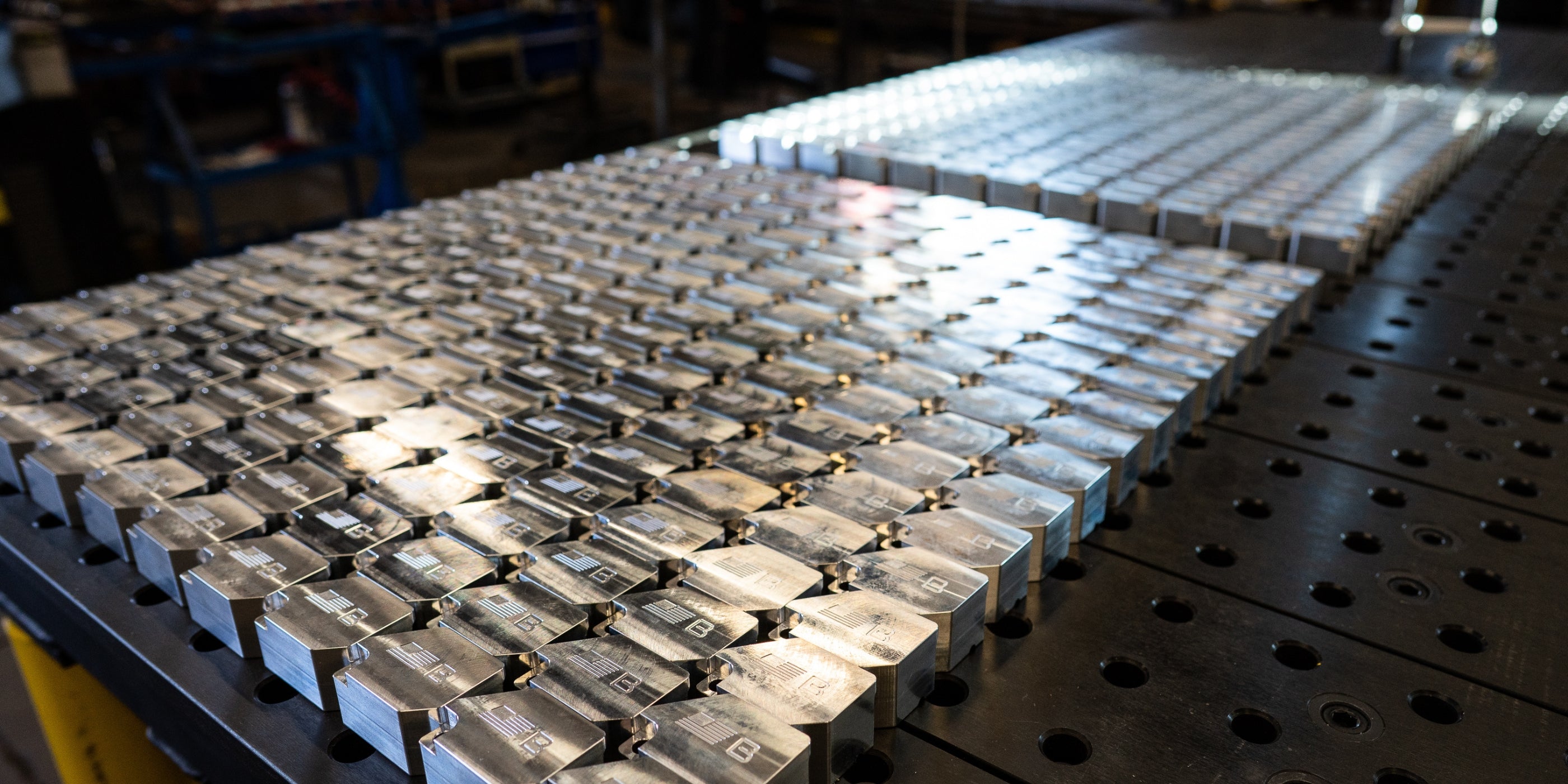

American-made Excellence

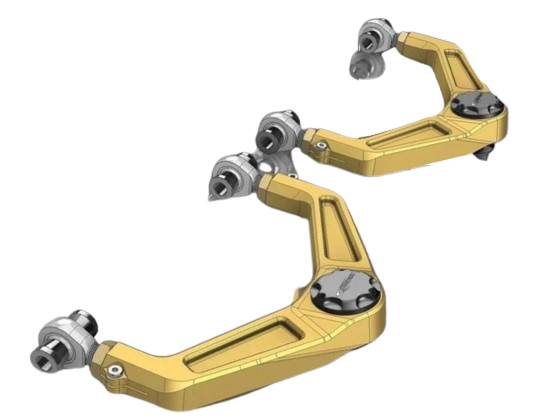

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: