Kryptonite

KRYPTONITE BOLT-IN UPPER BALL JOINT 1988-1998 C & K SERIES 2500/3500 TRUCKS

KRYPTONITE BOLT-IN UPPER BALL JOINT 1988-1998 C & K SERIES 2500/3500 TRUCKS

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

Description:

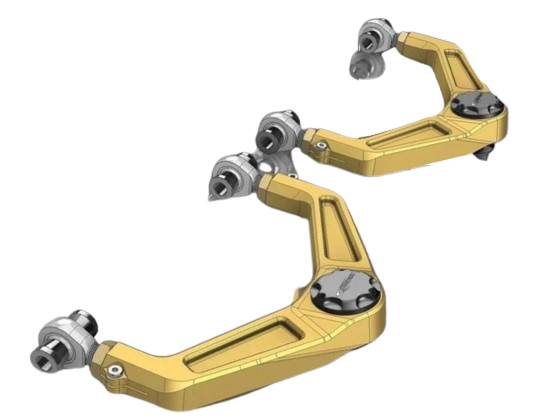

The Kryptonite KR6344 Bolt-In Upper Ball Joint represents the latest evolution of Kryptonite’s ball joint design. Improving not only on factory components, but even on previous Kryptonite generations. Every aspect of this joint was engineered to survive the demands of lifted trucks, oversized tires, aggressive alignment settings, and real-world abuse.

A massive chromoly stud, powdered-metal races, and a metal-on-metal internal design work together to deliver unmatched strength and articulation. The coil-spring compression system maintains consistent preload throughout suspension travel, reducing looseness and extending service life even under extreme conditions.

Finished with a corrosion-resistant gold zinc cap and protected by a thick rubber boot, the KR6344 is built for longevity, performance, and reliability. Whether you’re daily driving, towing, or pushing your truck off-road, this is a true heavy-duty upgrade over stock and aftermarket alternatives.

Upon install, these ball joints will require 4-6 pumps of grease. Going forward, the recommended service interval is about a half pump every 5,000–7,000 miles. Think of grease like blood in your body: without it, nothing survives. The boots are to keep dust and debris out and not to hold grease in so be careful not to over-grease.

Key Features:

- Heavy-Duty Engineered Design – Built specifically for the extreme demands of HD GM trucks, whether stock, leveled, or lifted.

- Forged High-Strength Housing – Optimized HD forging increases articulation and provides added clearance to prevent binding at full suspension travel.

- Heat-Treated Chromoly Ball Stud – Significantly stronger than factory studs and highly resistant to bending under heavy loads.

- Metal-on-Metal Internal Design – Eliminates weak factory-style internals for long-term durability in towing, off-road, and high-load applications.

- Powdered-Metal Internal Races – Designed for extreme wear resistance and consistent performance over the life of the joint.

- Coil-Spring Preload System – Maintains consistent internal tension as the suspension cycles, reducing looseness and extending service life.

- Premium Class 10.9 Hardware – Includes Kryptonite-supplied high-strength mounting hardware for secure, reliable installation.

- Greaseable Service Design – Pre-greased with Chevron Ultra EP2 grease and serviceable every 5,000–7,000 miles.

- Bolt-In Installation – Installs into the factory control arms using provided grade 8 hardware.

- Corrosion-Resistant Finishes – Black E-coat housing with a gold zinc-plated cap for long-term corrosion protection and a premium appearance.

Includes:

- 1 x Bolt-in Ball Joint

- 4 x 8mm Grade 10.9 Flanged Bolts

- 4 x 8mm Grade 10.9 Flanged Nuts

Fits:

1989-2000 Chevrolet / GMC C2500 / C3500

1988-2000 Chevrolet / GMC K2500 / K3500

1992-1999 Chevrolet / GMC K2500 Suburban

1996-2002 Chevrolet Express / GMC Savana 2500 / 3500 2WD

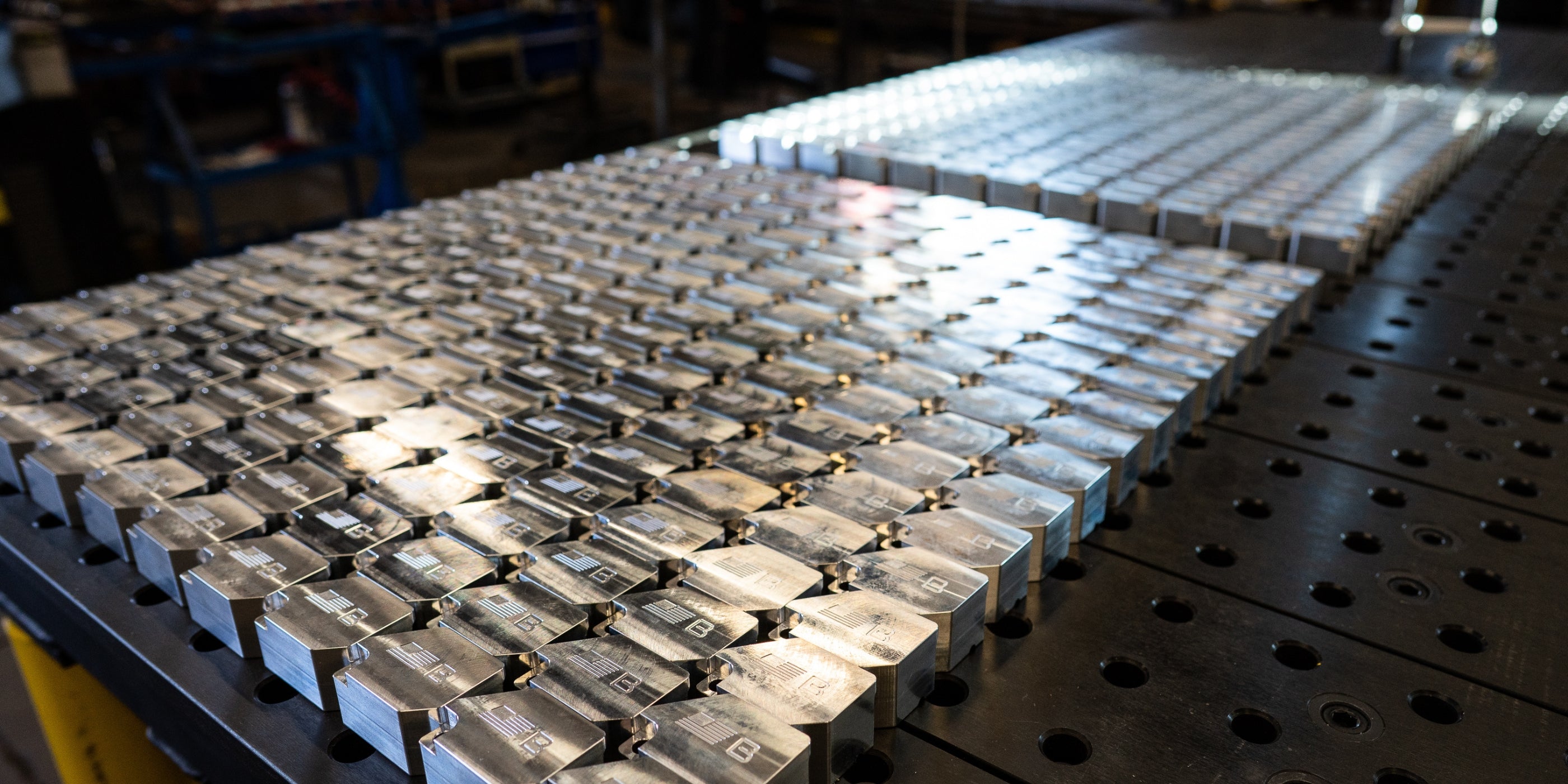

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: