Carli Suspension

'23+ F250/F350 Carli E-Venture System - Gas Motor

Sway Bar Option

Leaf Spring Option

Long-Bed Extension Harness

'23+ F250/F350 Carli E-Venture System - Gas Motor

Sway Bar Drop Brackets (CS-FSBD-LVL-1723) / None / No

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

overview

- Front Lift Height: +3.0" or +1.0" for Tremor

- Front Wheel Travel: 9.0"

- Rear Wheel Travel: 12.0"

- Shock Diameter: 2.5"

- Tire Fitment: 37" x 12.50"

The future has arrived. The E-Venture system stays two steps ahead of the driver thanks to data input from a provided engine mounted sensor and factory sensors via the OBDII port. The in-cab mounted “Brain” of this system processes the information through a proprietary algorithm. Thanks to this cornucopia of electronic goodness, the E-Venture System reads and reacts the terrain 250 times per second. The resulting ride is the Best. The “best” is an absolute statement… On road? Off Road? Gravel? Rutted, pot-hole filled unmaintained lease roads? Yes… Yes to all of it. The systems takes the capability of a 2.5″ Shock well beyond the threshold we’ve come to expect!

The truck will sit 3.0” higher in the front and have more wheel travel thanks to the lighter rate Carli Coil Springs. The Adjustable Track Bar centers the front axle and Stainless Brake Lines firm up braking and ensure there is enough line for the newfound travel. To round off the front end, we include Radius Arm Drop Brackets & 1° Caster Shims to correct caster and provide proper tracking. A fabricated, High-Clearance Bump Stop Drop to keep the springs clear from the contacting the factory bump stop.

The E-Venture system has been optimized to run with our Torsion Sway Bar; this is highly recommended as it lightens the most commonly neglected spring rate – the factory sway bar. From the Torsion Sway bar upgrade, one can expect a far more compliant feel and increased articulation with only slightly more body roll.

The rear should be optioned with the replacement Full Progressive Spring Pack (reduces capacity to a “light” ¾-ton). We’ve not tested the E-Venture system with the Progressive Add-a-pack.

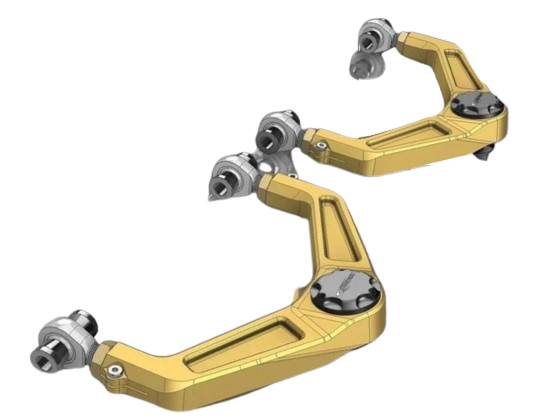

The shocks

The shocks themselves are top-tier construction. Hard-anodized aluminum bodies and reservoirs pair with 17-4 Stainless Shock Shafts will stand the test of time and elements. Billet Rod ends house teflon lined bearings to ensure industry leading performance and longevity.

Electronic Control Unit (ECU)

The “Brain” of the system is the ECU (Electronic Control Unit). The ECU Harness uses a large OEM-style connector with a rocker linkage to ensure it remains secured once fastened. We played with a few mounting locations in our R&D and the heat-cycling of our initial under-hood location proved detrimental to the ECU’s operable temperature range. We redesigned the harness to accommodate an in-cab mounting location (under the driver’s seat) and have had no overheating activity since.

The Harnesses

The ECU Harness is home to the connectors for the 4 harnesses in the system that allow all transmission of power and data. All connectors are unique to ensure connections to the ECU can’t be mixed up.

- Front Shock Harness: Male Connection on the harness, Female on ECU Harness. Connects 2 Front Shocks to the ECU.

- Rear Shock Harness: Female Connection on harness, Male on ECU Harness. Connects 2 Rear Shocks to the ECU.

- Power Harness: Wires Power and Ground for the system and includes a fuse Tap to indicate ignition power to the system.

- Communication Harness: OBDII, Touch Screen, and IMU Sensor Connections all feed into ECU.

The Sensors

Via the communication harness, the ECU accesses data from the engine mounted IMU (Inertial Measurement Unit). This unit senses any change in pitch/roll of the vehicle. The data from this IMU combines with information gathered from the OBDII port (Brake Pressure, RPM, Steering Angle, Throttle, etc.) to anticipate changes in chassis movement. Subsequently, it firms and softens the shocks where necessary to maintain a chassis that’s as level as possible.

Touch Screen Controls

The most important part of the interface is the one with which you interact. SDI put in a TON of work here to ensure a user-friendly interface with clean integration. We worked with them to take it a step further. The Bracket and Touch Screen mount in place of the bottom grab-handle bolt cover placing the touch screen both visible and out of the way. We provide a longer bolt to secure the screen. This location allows for clean routing of the wiring harness that feeds the Touch Screen without the need to trim the grab handle or weather-stripping.

Carli Modes

We worked with SDI to refine the drive modes; we wanted to increase the seat-of-the pants change between each mode. Offered on the E-Venture System are Mountain (Rock-Crawl), Street and Desert Modes. This is in order from softest/least sensitive to most controlled/active. These modes have been EXTENSIVELY refined; there’s nothing standard about them. All you, as the customer, need to do is select the mode and the system will activate the profile instantaneously.

Within each of the modes, users can refine the ride to their taste and it will auto-save the profile. There are adjustments for the front and rear shocks independently to increase control or comfort within each of the drive modes. We tuned and refined our recommended settings to be centered on ALL drive modes but that doesn’t mean you won’t prefer to run the front in the center of the adjustment and rear all the way toward comfort. Point is, it’s completely up to you!

Pro Mode

This mode takes it a step further for those that like to get nerdy. This mode allows users to adjust the Pitch, Roll, Brake, Throttle and Steering Response. Don’t worry, if your curiosity gets ahead of your knowledge or you failed to track your changes, we’ve implemented a “Restore Default” setting.

operating screen

While driving, the screen is defaulted to your interface showing the real-time correction at each corner. Numerical values between 0-10 show the adjustment intensity. You’ll notice these numbers change in speed of correction and amount of correction as the drive modes are altered. Swipe the screen to the right and you’ll find the roll/pitch read-out indicating the data being fed by the IMU.

This screen is also dimmable to a few different brightness to avoid distraction for those long, late-night drives where you won’t be looking at the touch screen.

hauling

Arguably the most handy feature for our customers is the Rear Load Adjustment. This gives the user incremental control over the rear dampers. When loaded, the rear can be adjusted to find the balance of comfort and support OR, as we preferred, max the rear support to prioritize load support. This adjustment makes a huge difference in the rear control when loaded; this will likely be the most championed feature.

Sway Bar Options

The Commuter System has been optimized for use with the Torsion Sway Bar; this sway bar upgrade is a HUGE ride quality upgrade. Maintaining the factory sway bar through use of the Sway Bar Drops or Extended Link Kit is only recommended for customers with snow-plows, in-bed campers or who are constantly hauling to the capacity of the truck.

Extended Sway Bar End Links:

- Combines End Links and Drop Brackets For Perfect Sway Bar Position

- Extended Length to accommodate Leveled Trucks

- 17-4 Stainless Steel, Greaseable and Fully Rebuildable

- Excellent Articulation

- Compatible with 2.5″ & 3.5″ Suspension Systems

Torsion Sway Bar Kit:

- Direct Fitment to Carli Leveling Lifts

- Replaces Immobile Factory Sway Bar with Custom Torsion Bar

- Huge Ride Quality Improvement

- Includes CS-FEL-LVL-17 Drop Brackets and Sway Bar Links

Leaf Spring Options

Progressive Add-A-Pack:

- Built in the U.S.A. By Deaver Leaf Spring

- Smooth, Progressive Design

- Supplied with Bump Stop Drops, U-bolts and hardware

- Pairs to Carli Leveling Lifts, provides 1/2"-1" high rear stance

- Eliminates the Factory Block

- Load capacity is maintained, ride quality is improved

Full Progressive Leaf Springs:

- Provides a 1/2", rear high stance to Carli Leveling Suspension Systems

- Reduced Overall Spring Rate to “light 3/4-ton” for a Better Ride

- Increased Progression (Spring Rate)

- Progressive Overload (Factory overload is a hard-stop)

- Dramatically Increased Suspension Travel

- Minimized Friction Throughout the Pack

- Optimal Ride for Commuter, Backcountry, Pintop and E-Venture

- Optimized Center Pin Location to Ensure Maximum Tire Fitment

- Includes Serviceable Bushings, New U-Bolts and Rear Bump Stop Drops

- Fitment: 2017-24 Ford F250/350 4x4, Diesel 3.5-4.0" Axle Tube

Full Progressive HD Leaf Springs (Constant +1000lbs in bed):

- Block eliminating, Full Progressive Spring Pack

- Heavy Duty Full Replacement Leaf Springs designed for those with constant 1,000lbs in the bed

- Includes new U-Bolts and Rear Bump Stop Drops

- Provides a 1", rear high stance on Matching 2.5" Leveling Suspension Systems

- 37" Tire Fitment

- Fitment: 2017-24 Ford F250/350 4x4, Diesel 3.5-4.0" Axle Tube

Wheel and Tire:

Factory Wheels SHOULD NOT be run with oversized tires. They’re known to rub the radius arm, sway bar and most concerning – Brake Lines. Factory tires and factory wheels will work without issue but we DO NOT recommend running oversized tires on factory wheels. On our Ford Leveling Systems, we recommend 17”-18” wheels, no more than 9” wide with 5.5” of backspacing with Carli Fabricated Radius Arms or 5” Backspace with factory arms; 5” will require a bit more trimming. Tires, 37×12.5” will fit with some trimming; 35” will likely fit without trimming. The more rubber, the better the small bump compliance will be at proper inflation pressures. The ride will firm up as you go larger in wheel diameter.

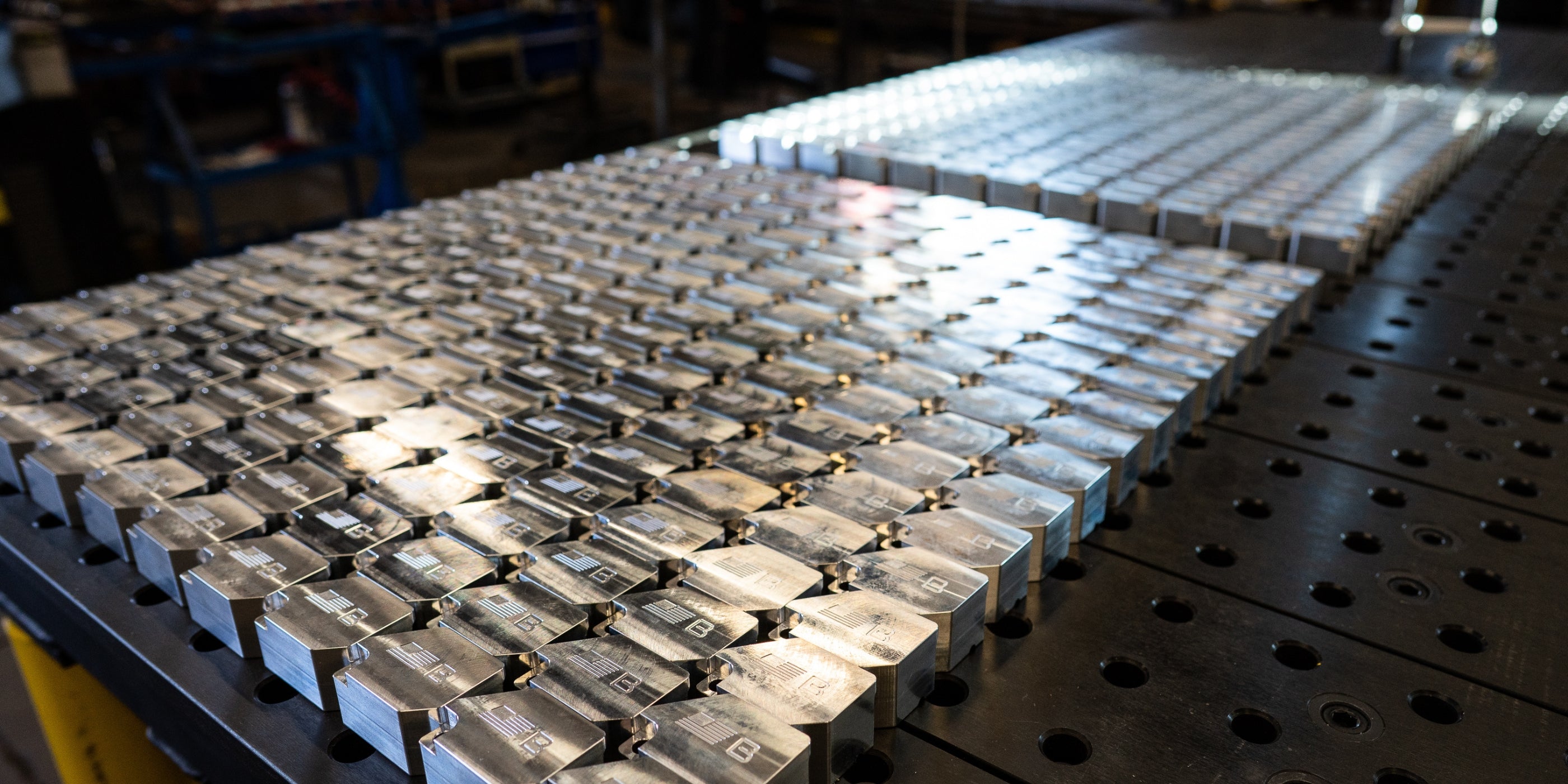

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: