Carli Suspension

'19-24 Ram 2500 Hemi Carli Dominator System

Rear Coil Option

Sway Bar Option

'19-24 Ram 2500 Hemi Carli Dominator System

R1 - (CS-DD30-19-H) / None

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

overview

- Front Lift: 3"

- Rear Lift: 0.5"-2"

- Front Travel: 8.5"

- Rear Travel: 11"

- Shock Diameter: 3.0"

- Tire Fitment: 37" x 12.50"

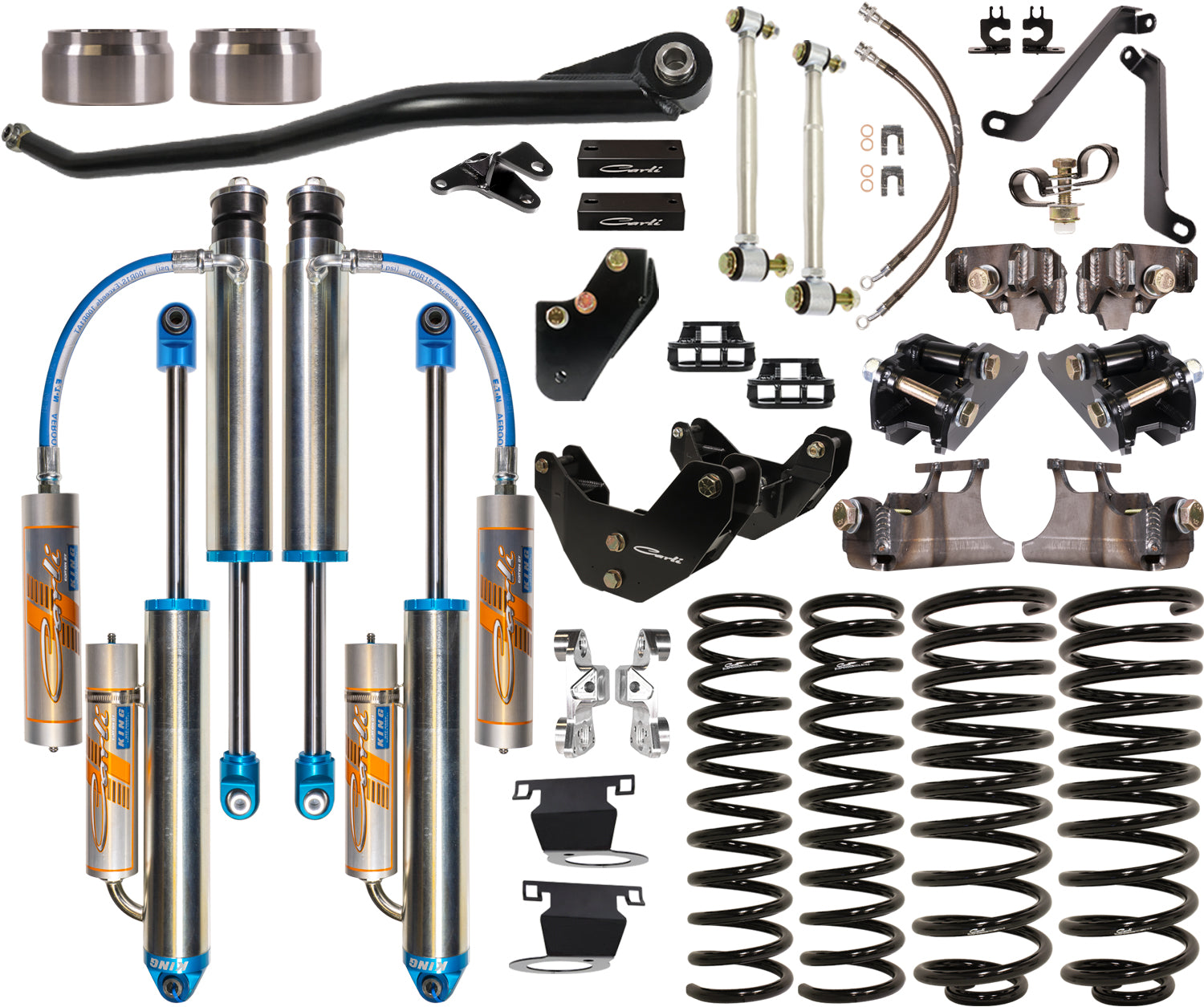

The Dominator is pinnacle offering in boasting front Carli Signature tuned, King 3.0” remote reservoir shocks so large, we needed to engineer mounting systems front and rear for them to cycle properly and strengthen the chassis for the larger shocks. As the old adage goes, there’s no replacement for displacement. In an effort to provide customers with the best product, we do not sell off-the-shelf King 3.0s. We designed a custom piston to determine proper base flow rates to ensure the shock works well in the heavy duty truck platform; we then tuned the shocks around the custom pistons based on seat-of-the-pants feel. We round off ALL our King shocks with shafts machined and polished from a solid piece of 17-4 Stainless. Unlike King’s standard shafts, there is no coating to wear off, weather is far less likely to hurt them and if there is a small chip, you can round the edges with emery cloth to ensure the seal housing isn’t damaged as they’re not brittle like the stock, hardened shafts.

The front, lower shock mount – we provide a 1/4″, boxed replacement for the weak, factory stamped, half-welded mount. The top index included in the side specific mount servers to locate the shock mount off the axle’s radius arm mount. Once the factory shock mount is removed, the Carli shock mount will be welded in place providing peace of mind and as much space as possible to cycle the 3.0″ diameter cylinders of the Dominator shocks.

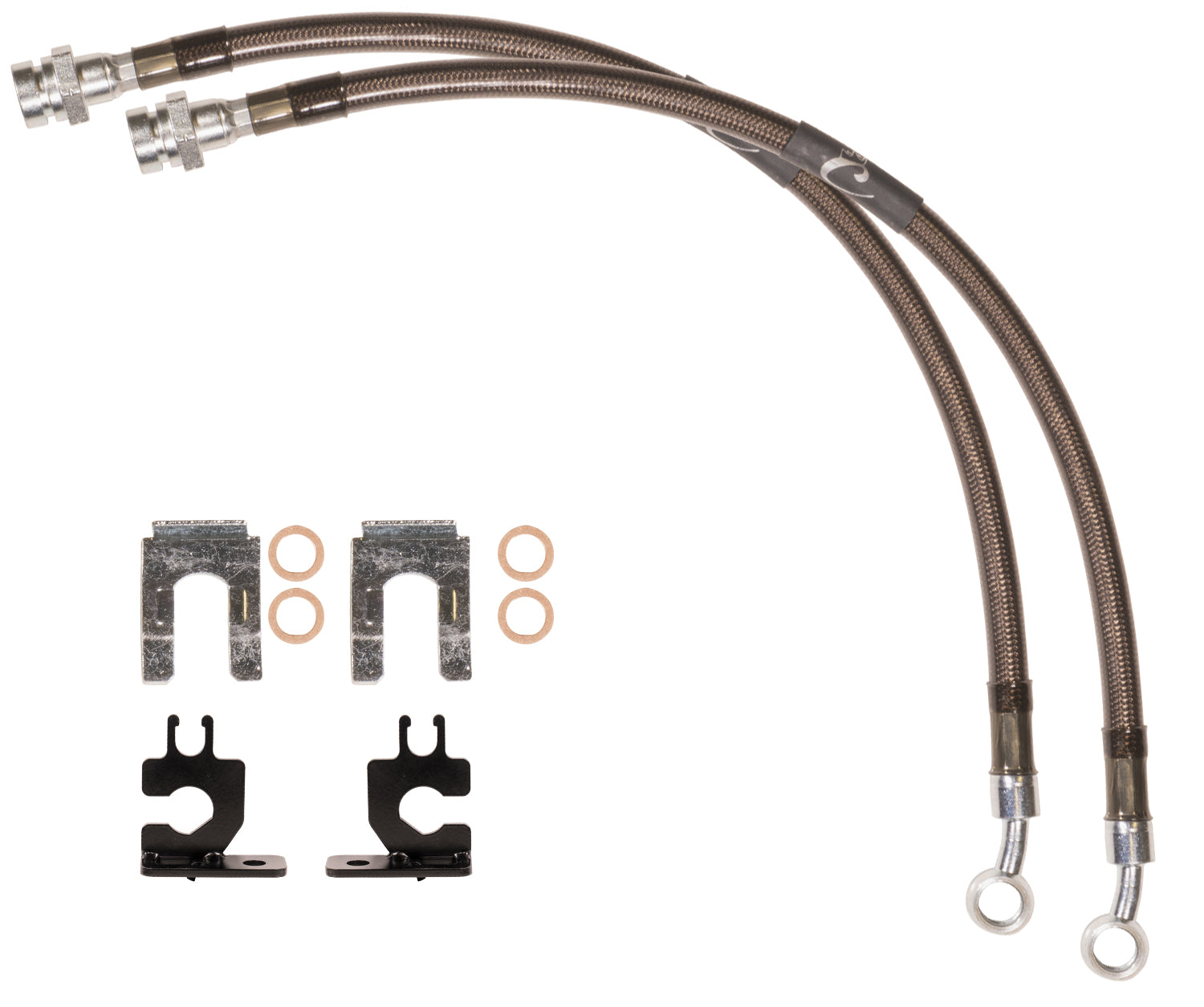

Even slightly offsetting the lower shock mount, the factory brake lines that come over the top of the radius arm need to be relocated to prevent the wiper cap (blue cap on the bottom of the shock body from which the shaft extends) contacting the factory lines. We provide extended Stainless Brake Lines and routing brackets to clear the brake lines from the shocks completely.

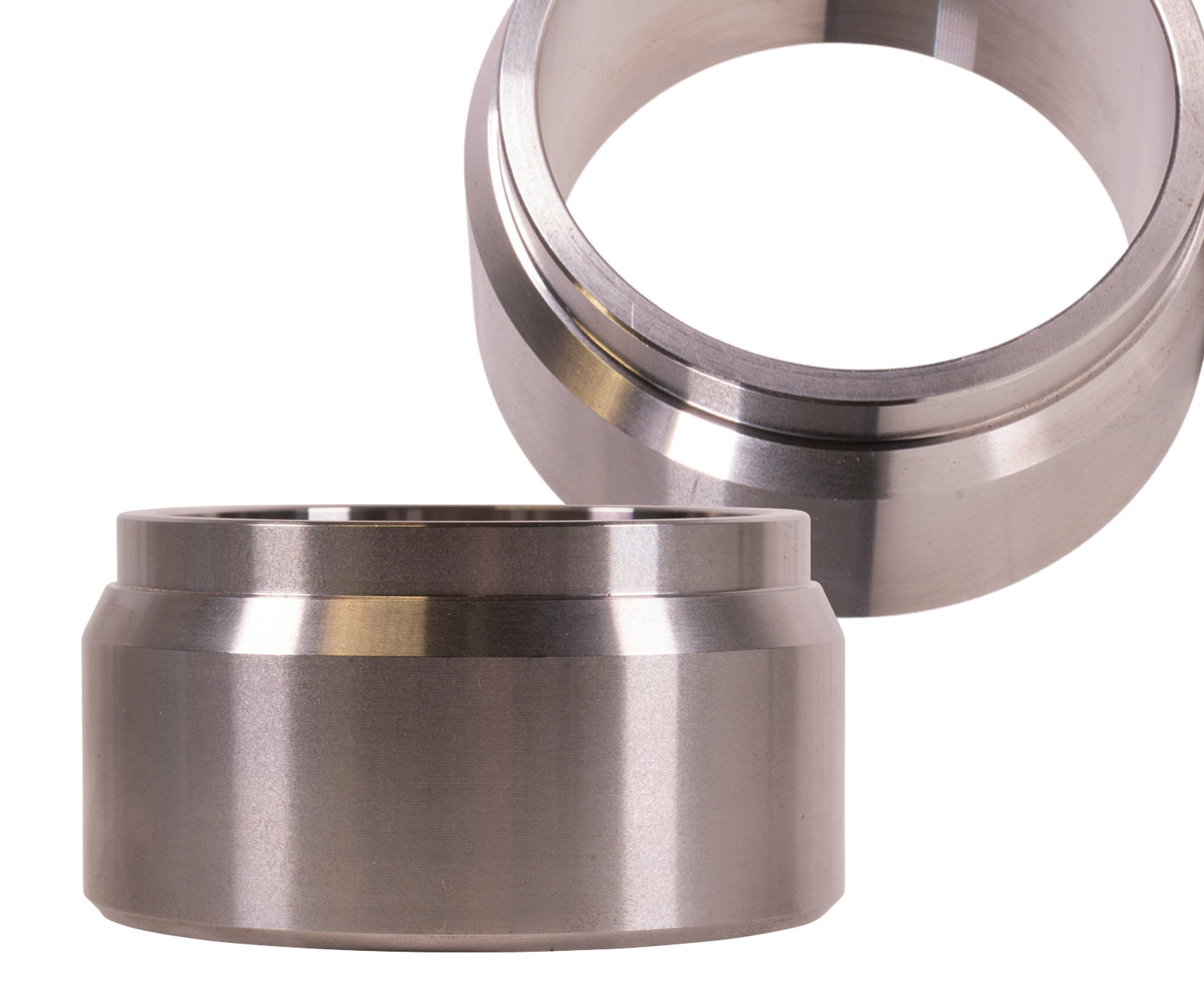

Another weak point…. The factory coil buckets offer very little support for the isolator – and thus, the coil – beyond a small hole to index its fitment. Combine this with a lower coil seat that’s angled forward and inward creating a spring pressure that induces both forward bowing and slipping coils. It’s not uncommon to see flattened isolators and springs that look like they’re going to slide forward and out of the bucket. Compound this factory shortcoming by adding big shocks, extended travel, and a heavy right foot off the pavement and additional support for the coils becomes cheap insurance against a coil re-installation off-the-grid! Machined from a solid piece of mild steel, these supports require front suspension disassembly, cleaning of the factory coil bucket, welding, priming and painting. Once in place, they appear factory as they’re nearly completely covered by the factory isolator. With these installed, your coil spring will not budge.

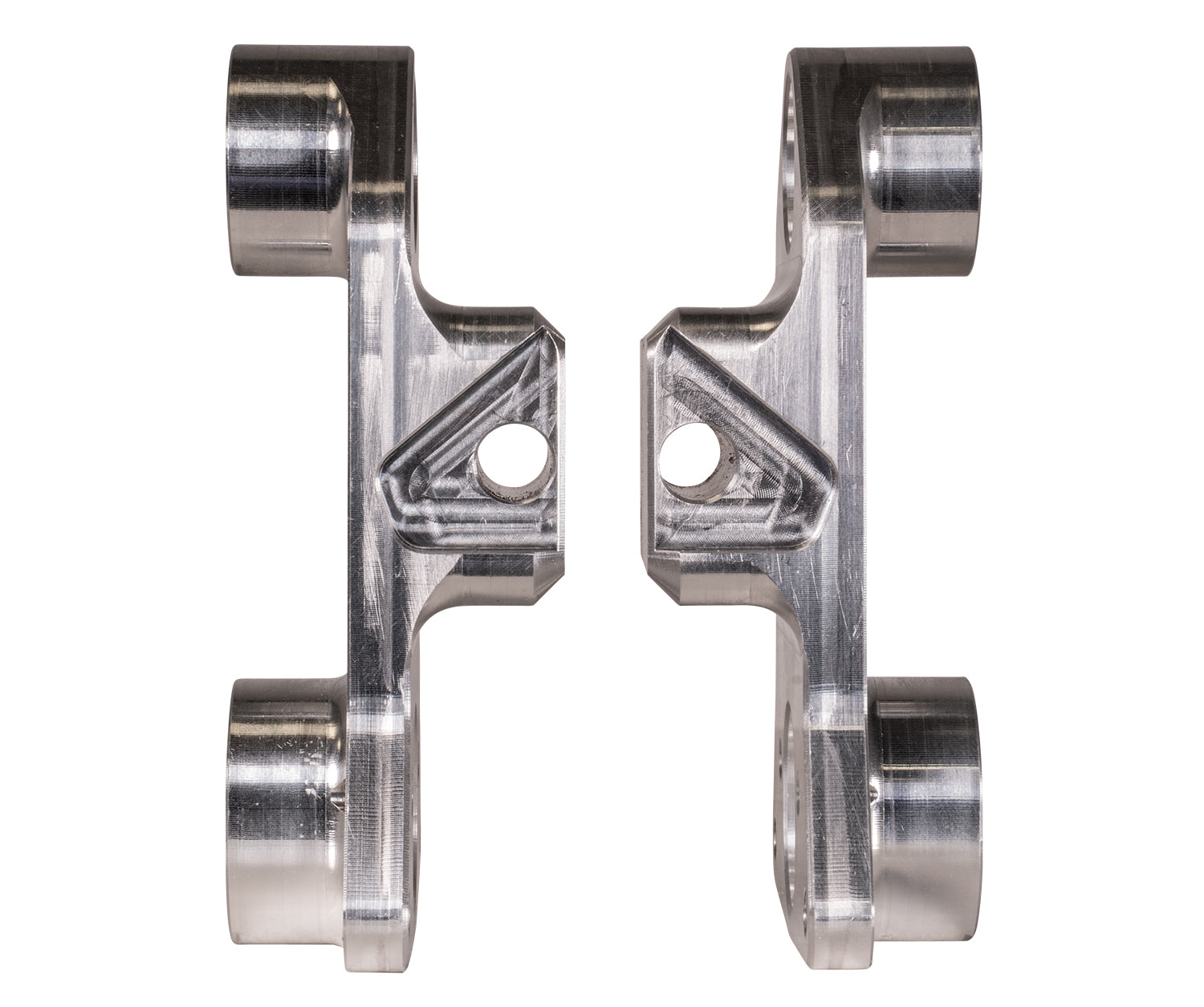

In the rear, we move the shocks from their extremely limiting factory location inside the frame-pocket. The tubular rear frame crossmember exits through the outside of the frame serving as the perfect location to which to weld our replacement upper shock mounts. The bottom shock mount sandwiches the factory mount utilizing 2 existing holes in the mount as well as the factory shock mounting location with the provided hardware. The mount extends forward and cants outward to align perfectly with the new upper mount while providing optimal tire clearance.

Because the shock position changes, the factory bed support must be modified, we provide a bolt-in solution to support the bed laterally from the factory control arm bracket once the factory support it removed.

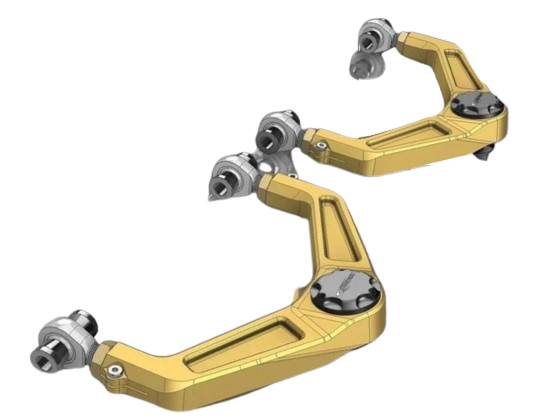

When pairing added down-travel with the taller ride height, the position of the factory, front sway bar will need to be altered as well. For this, we offer two options; Billet Sway Bar Drop Brackets or the replacement Torsion Sway Bar. The Billet Drop Blocks shift the sway bar down and forward to ensure the factory end links cycle properly throughout the entire extended travel range. Carli’s optional Torsion sway bar removes the entire factory sway bar assembly replacing it with a torsion bar supported by fabricated drop brackets and delrin bushings. Fabricated sway bar arms and dual 5/8” FK heim end links round off the package. This is the single best bang for the buck, ride-quality upgrade offered by Carli Suspension.

When lifting the front end of a straight axle truck, the front axle is pulled off-center unless the proper linkages are addressed. Three inches of front lift equates to an axle shifted toward the driver’s side ¾” and, in the radius arm equipped Rams, lightened caster and slight rearward axle shift. This system includes an Adjustable Track Bar to push the axle back toward the passenger side and provide a stronger link with less deflection for the lifted application. We also include Radius Arm Drop Brackets to recenter your caster adjustment and shift the axle forward to its new center of travel.

Everything is included to support flawless operation of all components. We include bump stop drops to ensure the shocks are cycling in their designed travel range as well as a rear track bar drop bracket minimizing the rear end “wag” associated with opposing track bar suspension designs.

Your truck will sit 3”-3.5” higher in the front (cab configuration dependent) with 50% more suspension travel than the factory platform thanks to the taller, lighter rate coil springs. We offer two base kits separated ONLY by the rear coil springs with which they’re spec’d

Option 1, R1 coils:

0.5″-1″ lift, reduced capacity soft-ride coils – Max 1,500lb. bed load.

Option 2, R2 coils:

2”-3” lift. These coils maintain the factory payload. The 2” lift below is shown on the heaviest Ram configuration – a Limited, Diesel Mega-Cab. If you have a shorter cab length or less optioned truck they’ll sit taller than pictured. Through our testing (up to 2,500lbs), we spec them as a factory capacity spring capable of 800lbs. constant payload (or more on lighter trucks) to level to 3.25″ front lift.

Sway Bar Options

Bump Stop Drop Brackets:

- In-house machined billet aluminum

- Hard-Anodized for corrosion resistance

-

Correct factory sway bar geometry on 3" Lift

Torsion Sway Bar Kit:

- Easily the best "bang for the buck" upgrade for ride quality

- Allows front suspension to move freely without giving up control

- Requires removal of electronic sway bar on Power Wagons

- Fitment: 2014+ 2500 4x4

- Compatible with 0"-4" Front Lift

- Torsion Bar may be Black or Silver Zinc; depends on supply-chain availability. NOT requestable.

Wheel and Tire:

This system will fit up to a 37” tire when utilizing wheels that are no more than 9” wide with 5.75-6” of backspacing. A 12.5” wide should fit with no rubbing on the factory radius arm and only minor trimming required, while a 13.5” will require more trimming and slightly more offset to fit properly. 35” tires will fit with VERY minimal, if any trimming. We Recommend running an 18” diameter wheel for optimal ride quality (more rubber = better small bump compliance) on a 35”-37” E-rated tire running 45psi front, 40psi rear when unloaded.

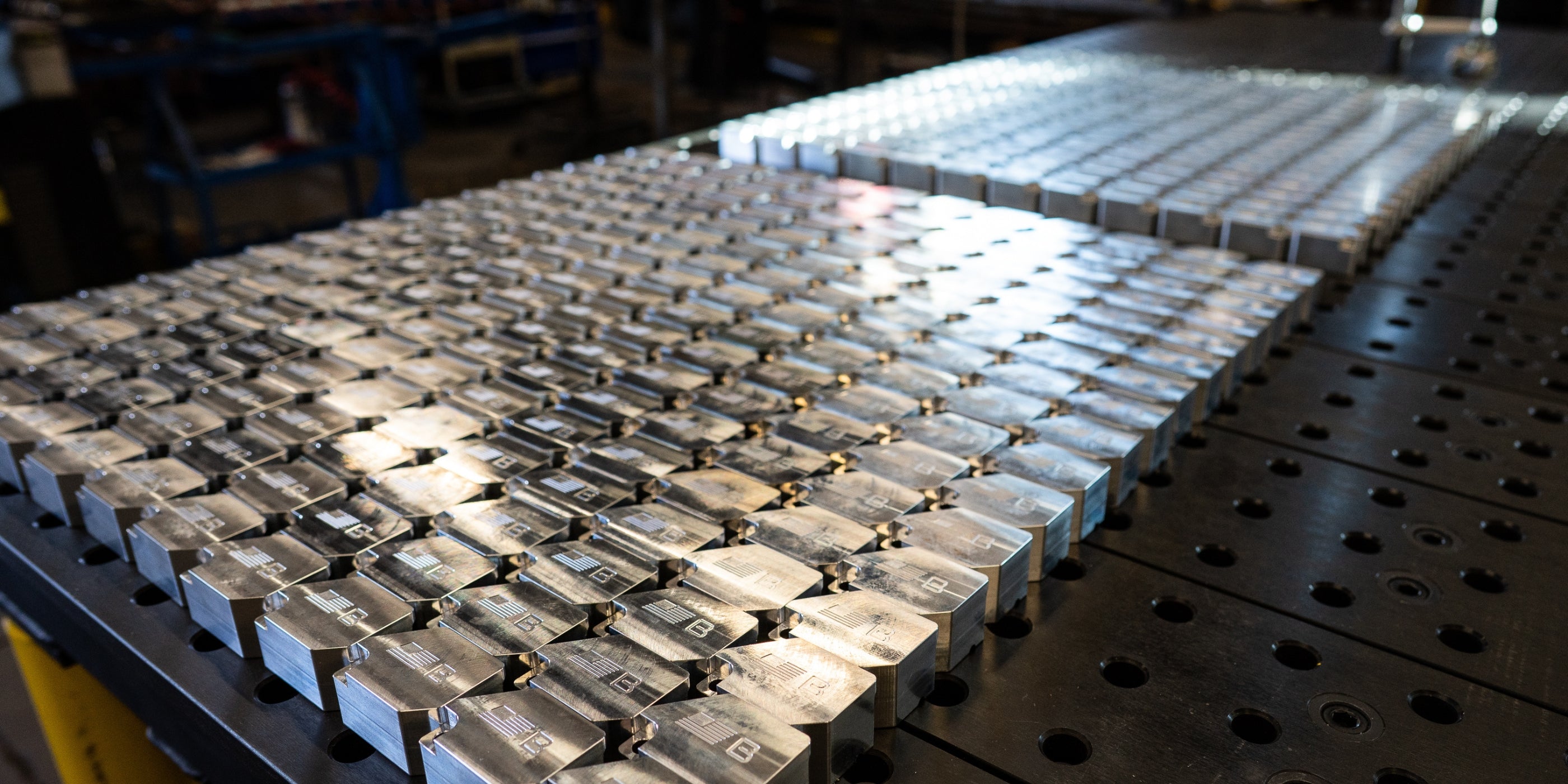

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: