Caliper Color

Powerbrake

'10-20 Ford F150/F150 Raptor X-Line Big Brake Kit

Caliper Color

'10-20 Ford F150/F150 Raptor X-Line Big Brake Kit

Red Anodize

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

ultimate stopping power

- Upgraded performance brake kits

- Minimum rim diameter: 18"

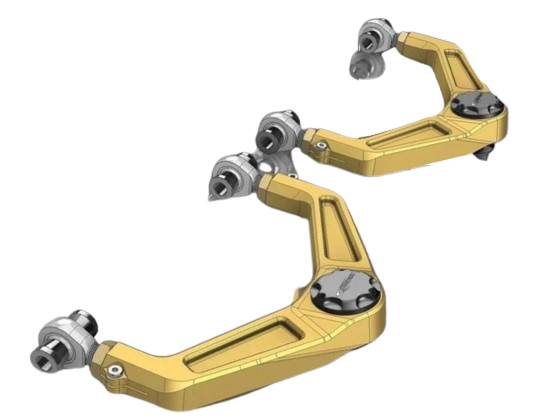

- X-Line billet 6-piston off-road calipers.

- Larger diameter rotor maximized for the truck application

- Rotor has internal curved, directional cooling vanes.

- Billet caliper mounting brackets.

- Stainless steel braided brake lines.

- All necessary mounting hardware for quick, easy bolt-on installation.

- Comprehensive install and bed-in instructions.

Rotors

The rotors utilized in our X-Line 4×4 big brake kits are crafted from a proprietary high-carbon cast iron alloy, ensuring exceptional durability and stability even during high thermal loads experienced in both street and off-road driving. Notably, these rotors feature curved, directional cooling vanes, significantly enhancing cooling efficiency by maximizing surface area and airflow compared to factory or OEM rotor designs.

For our X-Line 4WD rotors, we employ the proven “AT” slot pattern, striking a fine balance between functional aspects such as efficient removal of sand, mud, and water (especially when driving in rainy conditions or after river crossings) and practical aspects such as minimizing noise, vibration, and harshness (NVH) during braking. This slot pattern also delivers excellent bite and release characteristics.

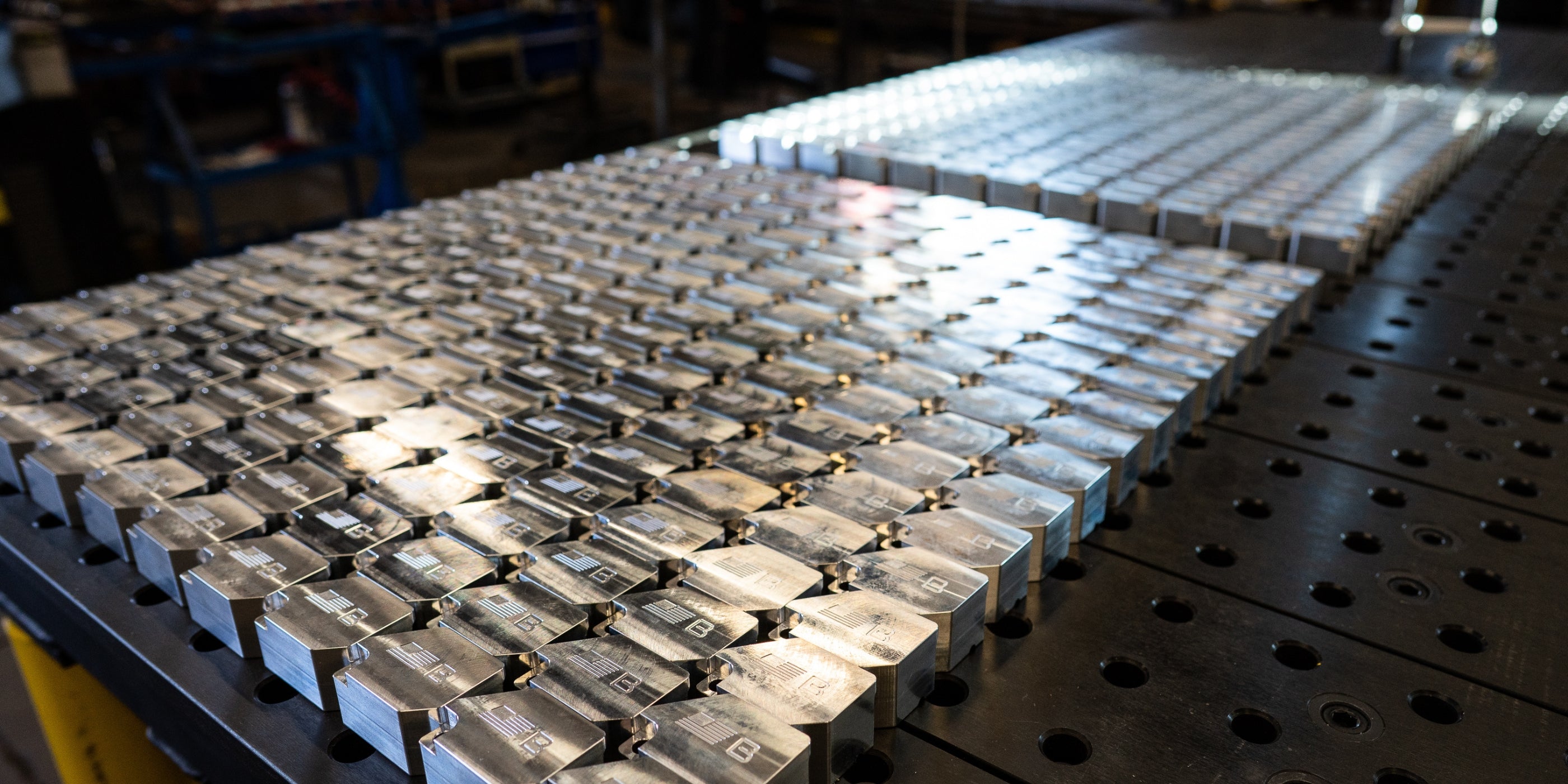

Every single Powerbrake rotor undergoes precise measurement for run-out and disc thickness variation (DTV) using Swiss measuring equipment. We prioritize quality control without relying on batch or statistical checks – each rotor undergoes individual measurement. Our machining tolerances surpass the industry norm by up to threefold.

Rotor Surface Coating

All our X-Line 4WD rotors feature a proprietary black surface coating. Before applying this coating, the rotors undergo chemical de-greasing to ensure the absence of machining fluids or contaminants that could negatively impact brake performance. The coating exhibits exceptional heat resistance and flexibility, preventing flaking or peeling during the rotor’s thermal expansion and contraction cycles.

Our X-Line 4WD rotors require no solvent-based cleaning or preparation. Simply make sure the car’s hub is clean and install the rotors as they come out of the box. The brake pads will remove the black coating in the pad track areas within the first 4-5 brake applications, while the un-swept areas of the rotor will retain the coating. Although the primary purpose of our rotor coating is to eliminate oils and contaminants during fitting (rather than providing corrosion protection), practical experience has shown that the non-swept areas of our coated X-Line 4WD rotors effectively resist unsightly surface rust formation, depending on environmental conditions. This results in a visually appealing appearance visible through the truck’s wheels and the perfect upgraded performance brake kits.

Rotor Maximum Temperature Recording (MTR) System

All our rotors feature our MTR system that provides a permanent record of the peak operating temperature reached by the rotor. This information is extremely valuable for understanding what is happening in your brake system. The thermal-paint tabs are applied to the outside diameter of the rotors (on both the inboard and outboard rotor plates). Each single-change paint color will change to white when a specific temperature is reached, hereby providing a record of the peak operating temperature of the rotor.

- Blue paint changes color at 527 deg F

- Green paint changes color at 860 deg F

- Orange paint changes color at 1022 deg F

- Pink paint changes color at 1166 deg F

Caliper Construction

At Powerbrake, we firmly believe in the advantages of machining our multi-piston calipers from solid billet. All our calipers are precision-machined using high-grade aerospace aluminum billets. Although machining from billet is an expensive manufacturing method, it yields a final product with exceptional strength and rigidity.

How do we offer our billet X-Line 4WD calipers at competitive prices? We achieve this through substantial investments in cutting-edge 5-axis CNC production equipment, ensuring maximum efficiency in caliper machining. The combination of machining from billet and the caliper designs enhanced through Finite Element Analysis (FEA) results in calipers with an impressive rigidity-to-size ratio. The slender profile of the calipers reduces unsprung weight and enhances wheel clearance.

Caliper Surface Finish

Caliper Logos

Caliper Cross-Bolts

Caliper Pistons

Internal Fluid Crossovers

Caliper Maximum Temperature Recording (MTR) System

Caliper Hardware

Caliper Mounting Brackets

Brake Lines

Brake Pads

The Powerbrake X-Line 4WD calipers (our upgraded brake kits) are designed around a pad profile which is available in wide range of brake pad compounds from most pad manufacturers worldwide. Our PB05 brake pad compound is in our opinion the very best pad compound on the world market for 4WD trucks. This ultra-high-performance material offers a big step up in performance and fade resistance over the pads that originally come with the truck. Stopping power, pedal feel and modulation are simply unmatched. In addition to the class-leading performance this pad compound will offer a good wear life and mileage.

Shipping & Returns

SHIPPING POLICY

There is a chance that your cart will display no shipping charges. Certain items populate a standard shipping rate, others are advertised as free shipping to the lower 48, and others (often multiple parts or larger orders) may not show a rate. There is nothing more to do on your end if it is free or flat-rate shipping.

If your order does require a shipping cost/option, our shipping department will determine the shipping charges, and we will email you the cost/options for your order to ship out. Once you receive that email, there will be a link to pay for the charges, or you can cancel the order and be fully refunded.

OFFERS OF FREE SHIPPING:

All free ground shipping offers only apply to shipping addresses in the continental United States. This notification will appear above the product information and on the cart page.

FLAT RATE GROUND SHIPPING:

Some products have a standard ground shipping policy if you require the product faster, please notify us in the notes section during checkout.

If you have special shipping requirements, please contact our sales department. Email us help@sdhqoffroad.com

PROCESSING YOUR ORDER:

If shipping costs need to be calculated/added, you will be emailed with an updated link to your order. Your updated order will include your order's shipping costs and be your original order with the letter "A" at the end. While checking for updates on your order, please add an "A" to the end of your order number, as your order number without the "A" will show canceled since it has been superseded.

FIBERGLASS SHIPPING POLICY:

Our shipping department takes the same time and effort in packaging your products as our engineers do in designing them. However, damage can still occur in shipping. Most of these damaged items can be easily repaired during install and or in paint prep. If this is not the case, the buyer must inspect the packaging and the products carefully upon receiving them, then accept the shipment and if need be, notate any damages and irregularities, such as crushed, torn, punctured, or broken parts on both the packaging and the product, on the freight bill or receipt at the driver’s presence. A signed receipt without any notation releases the carrier as well as SDHQ from any further damage claim. Discovery of damages after a clear delivery becomes the responsibility of the customer. The buyer must notify SDHQ of any damages within 24 hours. In cases of damage with proper notion on receipt, the carrier will determine whether to pay for the repair cost or replacement value of the damaged goods after damage inspection. Replacement value is the amount the buyer paid to SDHQ and is not negotiable. All disputes about the settlement amount shall be addressed with the carrier. SDHQ, under no circumstances, shall be liable for the damaged product or for subsequent settlement of the claim with the carrier.

POWDER COATED ROCK SLIDERS SHIPPING POLICY: While we pack with care, we advise against shipping powder-coated sliders due to the risk of scuffs/scratches during transit. Any shipping-related damage isn't covered by SDHQ.

GOOSE GEAR SHIPPING POLICY: All Goose Gear products are made-to-order. Once your order is placed, it cannot be cancelled or refunded. By checking this box, you acknowledge and agree to these terms. Thank you for understanding the unique nature of our custom manufacturing process.

RETURNS:

Some items may be eligible to be returned if returned as new within 30 days of shipping, with a 20% re-stocking fee. If eligible for return, the return amount will be for store credit. There are NO returns after 30 days from the date of receipt. Freight is nonrefundable. Refunds will be given on parts only and exclude labor or installation charges, shipping, or any other charges. All parts must be returned in the original package, cannot be damaged or installed, and must be in original condition.

For further info on our return policy, please visit the Online order returns page.

Shipping & Returns

SHIPPING POLICY

There is a chance that your cart will display no shipping charges. Certain items populate a standard shipping rate, others are advertised as free shipping to the lower 48, and others (often multiple parts or larger orders) may not show a rate. There is nothing more to do on your end if it is free or flat-rate shipping.

If your order does require a shipping cost/option, our shipping department will determine the shipping charges, and we will email you the cost/options for your order to ship out. Once you receive that email, there will be a link to pay for the charges, or you can cancel the order and be fully refunded.

OFFERS OF FREE SHIPPING:

All free ground shipping offers only apply to shipping addresses in the continental United States. This notification will appear above the product information and on the cart page.

FLAT RATE GROUND SHIPPING:

Some products have a standard ground shipping policy if you require the product faster, please notify us in the notes section during checkout.

If you have special shipping requirements, please contact our sales department. Email us help@sdhqoffroad.com

PROCESSING YOUR ORDER:

If shipping costs need to be calculated/added, you will be emailed with an updated link to your order. Your updated order will include your order's shipping costs and be your original order with the letter "A" at the end. While checking for updates on your order, please add an "A" to the end of your order number, as your order number without the "A" will show canceled since it has been superseded.

FIBERGLASS SHIPPING POLICY:

Our shipping department takes the same time and effort in packaging your products as our engineers do in designing them. However, damage can still occur in shipping. Most of these damaged items can be easily repaired during install and or in paint prep. If this is not the case, the buyer must inspect the packaging and the products carefully upon receiving them, then accept the shipment and if need be, notate any damages and irregularities, such as crushed, torn, punctured, or broken parts on both the packaging and the product, on the freight bill or receipt at the driver’s presence. A signed receipt without any notation releases the carrier as well as SDHQ from any further damage claim. Discovery of damages after a clear delivery becomes the responsibility of the customer. The buyer must notify SDHQ of any damages within 24 hours. In cases of damage with proper notion on receipt, the carrier will determine whether to pay for the repair cost or replacement value of the damaged goods after damage inspection. Replacement value is the amount the buyer paid to SDHQ and is not negotiable. All disputes about the settlement amount shall be addressed with the carrier. SDHQ, under no circumstances, shall be liable for the damaged product or for subsequent settlement of the claim with the carrier.

POWDER COATED ROCK SLIDERS SHIPPING POLICY: While we pack with care, we advise against shipping powder-coated sliders due to the risk of scuffs/scratches during transit. Any shipping-related damage isn't covered by SDHQ.

GOOSE GEAR SHIPPING POLICY: All Goose Gear products are made-to-order. Once your order is placed, it cannot be cancelled or refunded. By checking this box, you acknowledge and agree to these terms. Thank you for understanding the unique nature of our custom manufacturing process.

RETURNS:

Some items may be eligible to be returned if returned as new within 30 days of shipping, with a 20% re-stocking fee. If eligible for return, the return amount will be for store credit. There are NO returns after 30 days from the date of receipt. Freight is nonrefundable. Refunds will be given on parts only and exclude labor or installation charges, shipping, or any other charges. All parts must be returned in the original package, cannot be damaged or installed, and must be in original condition.

For further info on our return policy, please visit the Online order returns page.

Quality

We pride ourselves on offering only top-tier products, handpicked through strategic partnerships with the industry's elite.

When you choose us, you're investing in unparalleled quality and craftsmanship.

Learn more about what 'SDHQ Built' means to us here.

Quality

We pride ourselves on offering only top-tier products, handpicked through strategic partnerships with the industry's elite.

When you choose us, you're investing in unparalleled quality and craftsmanship.

Learn more about what 'SDHQ Built' means to us here.

Secure Payment

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

We accept payments with :

Visa, MasterCard, Shop Pay, PayPal, Apple Pay, Discover and more.

Secure Payment

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

We accept payments with :

Visa, MasterCard, Shop Pay, PayPal, Apple Pay, Discover and more.

find everything you need?

SDHQ Built Products

Discover the robust, American-made range of SDHQ products, where superior quality meets outstanding performance. Crafted at our headquarters, our gear is built to enhance your driving experience.

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: